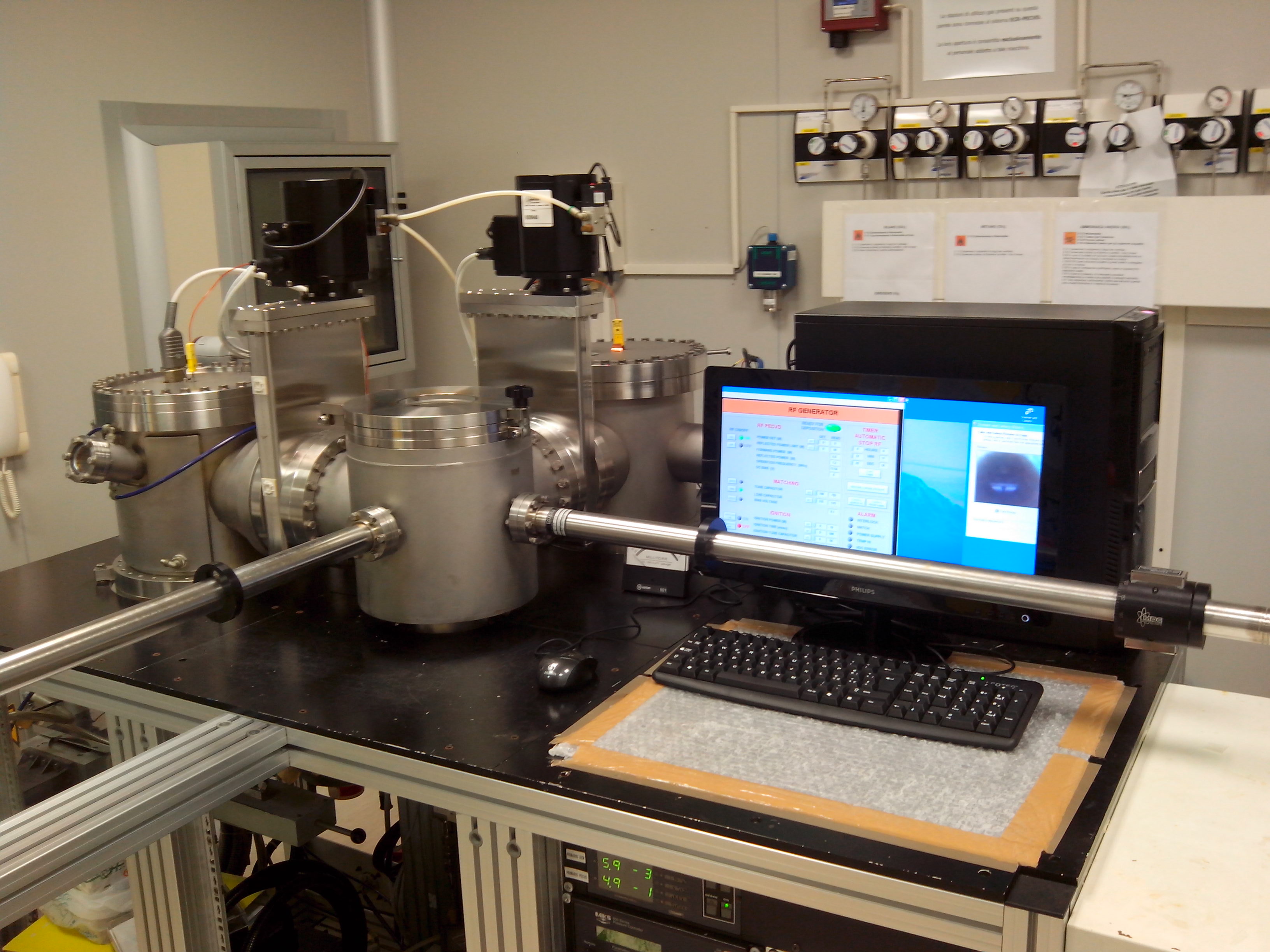

ECR/RF PECVD deposition system

ECR/RF PECVD Deposition System

ECR/RF PECVD Deposition System

The integrated double chamber electron cyclotron resonance (ECR) / radio frequency (RF) plasma enhanced chemical vapor deposition (PECVD) system is available for the deposition of Si-based and C-based amorphous, microcrystalline, and polycrystralline materials, such as a-Si:H, mc-Si, nc-SiC, a-SiOx, a-SiNx, a-SiCx, a-SiOxNy, a-C:H, a-CN:H.

Available gas lines for RF-PECVD reactor

- SiH4 ( 60 sccm maximum gas flow rate)

- CH4 ( 70 sccm maximum gas flow rate)

- NH3 (146 sccm maximum gas flow rate)

- CO2 ( 72 sccm maximum gas flow rate)

- H2 (202 sccm maximum gas flow rate)

Available gas lines for ECR-PECVD reactor - downstream

- SiH4 ( 60 sccm maximum gas flow rate)

- CH4 ( 70 sccm maximum gas flow rate)

- NH3 (146 sccm maximum gas flow rate)

- CO2 ( 72 sccm maximum gas flow rate)

- H2 (202 sccm maximum gas flow rate)

Available gas lines for ECR-PECVD reactor - upstream

- H2 (101 sccm maximum gas flow rate)

- Ar (139 sccm maximum gas flow rate)

Pumping system

- separated pumping system for each reactor

- turbomolecular and mechanical pump in sequence

- all pumps purged by nitrogen

- ulimate vacuum 1E-8 Torr

Heating unit

- maximum substrate temperature ~350 °C

Other features

- Load lock chamber for improved film purity

- Deposition pressures:

- RF-PECVD: 100 mTorr - 1 Torr

- ECR-PECVD: 10 - 25 mTorr - 4" maximum substrate diameter