Bioactive surfaces

This research activity deals with the development of biocompatible and bioactive surfaces for medical and dental applications. The modification of surfaces to improve their properties is achieved either by the application of plasma-assisted physico-chemical treatments, or by the deposition of thin film coatings by plasma-assisted techniques.

Thin-film coatings can improve the compatibility between the prostheses and the living tissue, avoiding the contact with potentially dangerous materials and blocking the diffusion in the body of poisonous elements coming from the bulk materials. Moreover, they can reduce the friction coefficient between the prostheses and parts of the body and can avoid the processes of prostheses deterioration, which could promote the release of particles (often poisonous) in the living tissue. Since materials used for the fabrication of medical prostheses can also include toxic contaminants that can diffuse in the body, antidiffusive characteristics of several thin-film materials can be of great aid in improving bicompatibility of these materials. In the specific field of dental prostheses, thin-film coatings can greatly improve the aesthetic features of the prostheses by changing in a controllable way their properties of light reflection, thus increasing the brightness. Moreover they can avoid or reduce the degradation of the light reflection due to the increase of roughness with time. The presence of the saliva and of the byproducts of food mastication subjects the prostheses to continuous contact with several kinds of chemical substances, many of which are strongly aggressive, and is another cause of possible material degradation. Also in this case, the use of thin-film based coatings can be of great help, since the resistance to chemical attack of the coating materials is usually much stronger respect to the ones of which the prostheses are made.

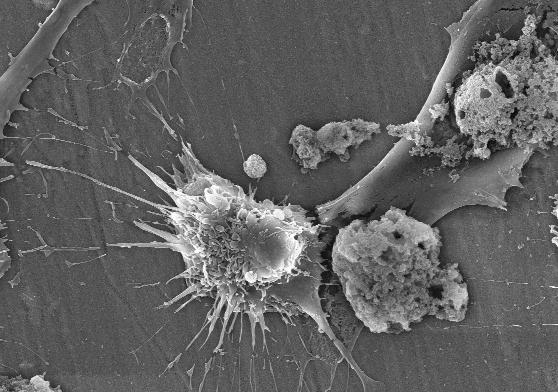

Thin film coated dental implant, seen at the scanning electron microscope.

Thin films and surface treatments are also suitable to provide surfaces with the capability to improve the adhesion of cells, thus accelerating the osteointegration process of implants in the human body.

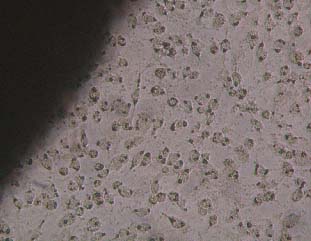

Osteoblasts adhered on a surface, seen at the scanning electron microscope.

Materials of great interest for application to medical prostheses and implants are silicon-based thin film alloys, since they show important properties of biocompatibility and bioactivity, together with good mechanical and chemical properties. An example is silicon oxide in its amorphous form (a-SiOx), which shows characteristics of hardness and mechanical resistance similar to the ones of glass and optical properties of great transparency. Some of these properties can be tuned by changing the relative atomic content of Silicon and Oxygen inside the material. Other important materials are silicon nitride (a-SiNx) and silicon oxinitride (a-SiOxNy), which are able to provide high barrier properties against the diffusion of poisonous elements.

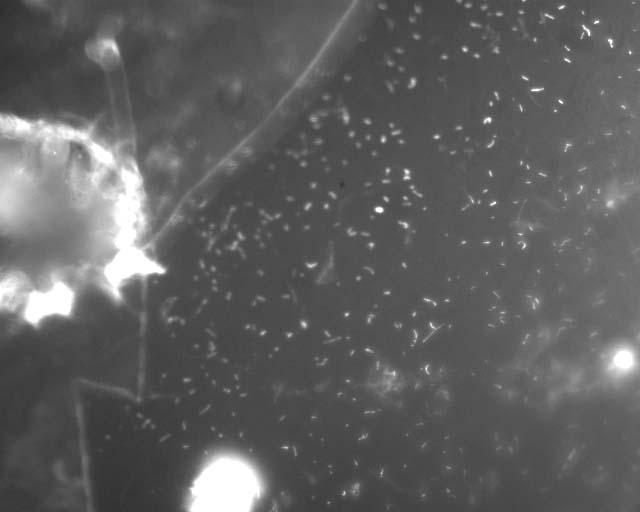

Cells adhered on a uncoated (left) and coated (right) surface of a dental resin:

on the uncoated surface the cells are died due to the cytotoxic action of the material, while on the coated sample they are alive.

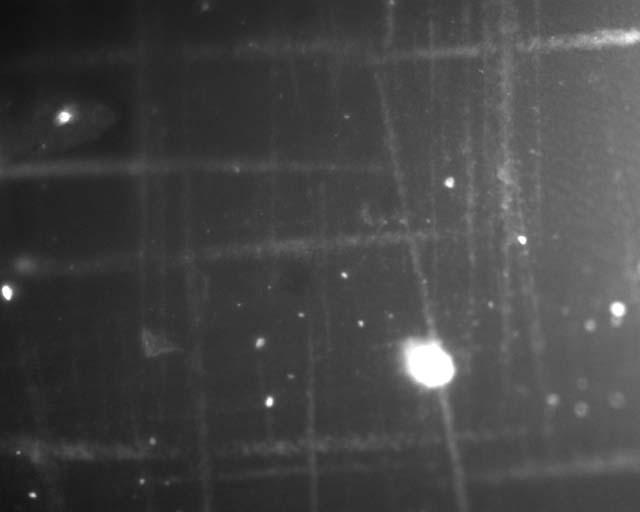

S.Mutans bacteria adhered on a uncoated (left) and coated (right) surface of a dental resin:

on the coated surface the number of adhered bacteria is considerably lower.

The fabrication of this kind of coatings can be performed by different technologies, that are usually grouped in three types: physical vapor deposition (PVD), chemical vapor deposition (CVD), plasma enhanced chemical vapor deposition (PECVD). Generally speaking, the use of plasma assisted techniques allows the deposition of films at lower temperatures and thus gives the possibility to grow on materials that cannot resist to high temperatures, such as resins or plastics. Surface modifications are usually achieved by means of plasma-assited processes, involving the exposiotion of surfaces to the action of several types of plasma, obtained by the excitation of gases.

Contact information

Pietro Mandracci

Tel. +39 011 090 7383

pietro.mandracci@polito.it

Publications

"Reduction of bacterial adhesion on dental composite resins by silicon-oxygen thin film coatings", P Mandracci, F Mussano, P Ceruti, C F Pirri, S Carossa, Biomedical Materials 10 (2015) 015017.

"Si-Based Amorphous Thin Films for the Performance Improvement of Dental Prostheses and Implants", P Mandracci, R Gazia, F Mussano, S Carossa, C F Pirri. In: Prostheses: Design, Types and Complications (2012) Edited by :D. F. Colombo and G. S. Rossi. Nova Science Publishers.

"AlNx and a-SiOx coatings with corrosion resistance properties for dental implants", R Gazia, P Mandracci, F Mussano, S Carossa, Surface and Coatings Technology 206 (2011) 1109-1115.

"a-SiOx coatings grown on dental materials by PECVD: compositional analysis and preliminary investigation of biocompatibility improvements", P Mandracci, P Ceruti, C Ricciardi, F Mussano, S Carossa, Chemical Vapor Deposition 16 (2010) 29-34.

"Low temperature growth of thin film coatings for the surface modification of dental prostheses", P Mandracci, F Mussano, C Ricciardi, P Ceruti, F Pirri, S Carossa, Surface & Coatings Technology 202 (2008) 2477-2481.

"Growth of amorphous thin-films on dental prostheses for the improvement of their performance", M Perucca, C F Pirri, P Mandracci, C Carossa, P Ceruti. In: Proceedings of the 17th International Symposium on Plasma Chemistry (2005).

Collaborations

University of Turin, Department of Surgical Sciences, Dental School