Environmental Applications

Water Metal Analyzer

The analysis of water quality in the vicinity of oil or gas platforms takes place periodically. Water samples are collected in-situ and then analysed in specialized laboratories, primarily using chromatographic or spectroscopic techniques for the organic/inorganic contaminant identification. The exploitation of reservoirs, whether they are oil or gas, involves the production of waste, including the produced formation water (PFW). PFW is the most relevant type of effluent in the production phase of hydrocarbons on offshore installations, both for the generated volumes and for the level of pollutants potentially present. Downstream the purification treatment, the production of water for the sea discharge appears as a heterogeneous mixture, constituted by an aqueous phase with the residual solid material in suspension. The aqueous phase contains inorganic chemical species (salts, metals and radioisotopes) and organic (mono-compounds, polycyclic aromatic, aliphatic hydrocarbons, ...).

Sampling and related delivery does not allow mapping contaminant plumes nor establishing a correlation between the contaminant(s) and a hypothetical source, so this type of approach cannot be exploited to implement strategies for prevention of environmental disasters. Thus, it is desirable that the current sampling methodology evolves into a more frequent and refined environmental monitoring approach.

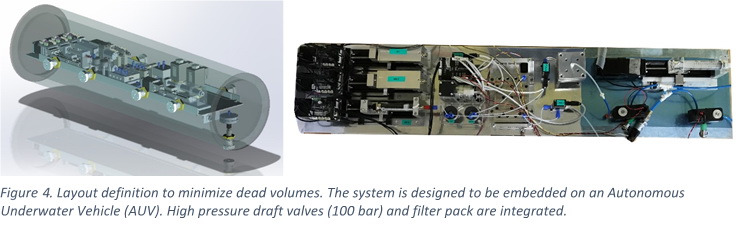

The offered solution to significantly improve the operational scenario is that of a sensing system capable of sampling daily (or even more frequently) the waters nearby a site of interest to assess any presence of contaminants. A real-time mapping of water quality in proximity of offshore hydrocarbon production sites through AUV (Autonomous Underwater Vehicle) systems is currently under development.

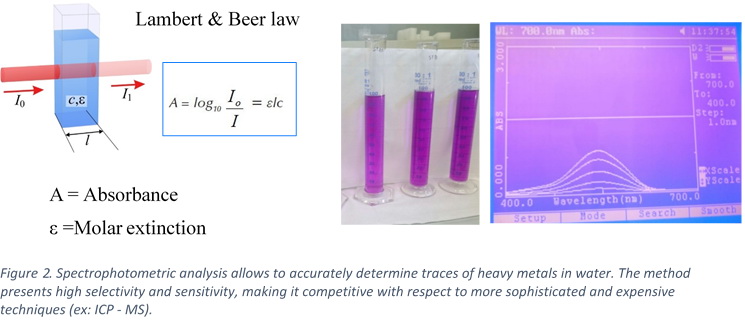

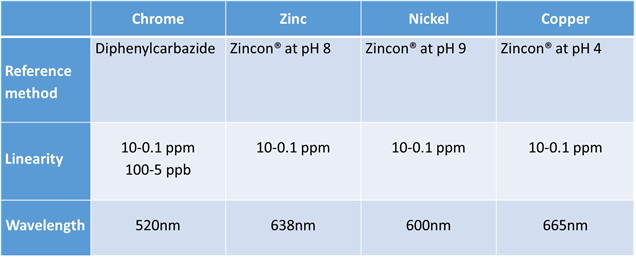

The common principle of water analysis is that the sample is mixed with reagents, which react specifically with the constituent to be analysed. In most cases a coloured compound or complex is formed. The intensity of the colour is a measure for the concentration and can be quantified using UV/Vis spectroscopy. Here the attenuation of radiation at a specific wavelength can be measured and a relation between absorbance and concentration is made by establishing a calibration curve. The absorbance increases with the concentration of the analyte in the water accordingly to the well-known Lambert & Beer law.

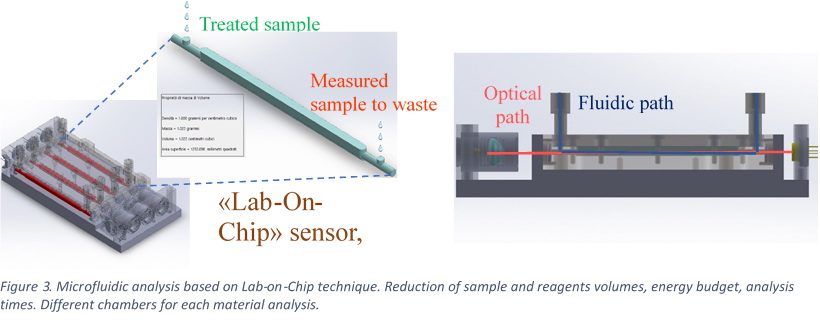

The aim of our research is an optimized method to be moved to a miniaturized and portable device where reagents and samples will be dosed periodically by a microfluidic system able to manage minimum volumes of liquids. For sample irradiation a laser diode emitting at the required wavelength will be used. Data will be collected and processed by a software providing the metal concentration, alarming in case of legal limit overcoming.

The design of the sensing platform mounted on AUV takes advantage of microfluidic (Lab-On-Chip) technologies for the management of the fluids and in-situ analysis of marine water samples. The approach involves a significant reduction of the sample and reagents volumes, prolonged monitoring and a greater areal coverage around platforms without any noticeable loss of performance in terms of sensitivity.

To provide greater flexibility, the platform has been designed with a structure of independent but integrated modules (sampling, filtering, sample pre-treatment, analysis, data storage, reagent and any reaction products storage), so as to contain as much as possible the overall dimensions and in order to customize the platform according to the specific requirements.

Contact information

Luciano Scaltrito

Tel. +39 011 090 7337

luciano.scaltrito@polito.it

Sergio Ferrero

Tel. +39 011 090 7337

sergio.ferrero@polito.it

Micro Hot-Plate for H2S Sensing

In most industries (the oil & gas above all) one of the basic points of a security plan to reduce the risks for the staff, for the plant and the surrounding environment is the adoption of appropriate alarm systems, such as those based on gas sensors. These allow to take preventive remedies and actions to be taken as parts of a comprehensive, automated and integrated control and safety plan of a facility or a processing site.

In most industries (the oil & gas above all) one of the basic points of a security plan to reduce the risks for the staff, for the plant and the surrounding environment is the adoption of appropriate alarm systems, such as those based on gas sensors. These allow to take preventive remedies and actions to be taken as parts of a comprehensive, automated and integrated control and safety plan of a facility or a processing site.

The detection of toxic and/or hazardous gas mixtures for the environment and for the workplaces (and in particular, but not exclusively, H2S) finds a particular application in the field of industrial processes, safety at work, control and environmental monitoring.

In particular, the H2S detection is strategically important for many application scenarios. The focus for the H2S is due to its inherent dangers. H2S is a colorless gas, extremely dangerous, characterized by a pungent odor, similar to that of rotten eggs. Even at very low concentrations it is however extremely toxic and can attack and inhibit the smell. In addition, in the appropriate mixing conditions with air or oxygen (flammability range from 4.3 to 45.5%) can be explosive. It dissolves in liquids, therefore, it may be in any container, tank or means of transport of liquids such as oil, water, fuels or emulsions. It has a broad spectrum of toxicity effect, although the nervous system and cellular respiration are the first systems to be attacked following exposure.

It can be found in different working environments, mainly, but not exclusively, those related to oil industry (refineries, oil wells, ...). It may accumulate wherever there is a mixture of hydrocarbons and sulfides. There are several organic sources where you can find the H2S, some almost unexpected, as the holds of ships, mine shafts, pulp mills, water purification plants, quagmire, drains and sewers (H2S is a natural product and is generated by the organic decomposition, for which it is present e.g. also in landfills).

The aim of the activity is therefore the study of a solid state sensor for the monitoring of H2S, with innovative features compared to the state-of-the-art and that integrates advanced technologies. For this purpose, the developed device is based on the convergence of different technologies:

• nanotechnologies: for the growth and the synthesis of the active material (through the partnership with IMEM-CNR) sensitive to the presence of the target gas even at very low concentrations and based essentially on nanostructures of semiconducting metal oxides (ZnO, SnO2, TiO2, ...). The nano structures investigated are Tetrapods (TPs), nanosheets (NSs), or combinations thereof;

• microtechnology and MEMS technologies: for the realization of the suspended microstructure (micro-membrane or micro-hot-plate structure) of electrically and thermally insulating material on which is integrated the above referred active material and the devices for its control (thin film platinum heater and temperature sensor ).

Contact information

Matteo Cocuzza

Tel. +39 011 090 7392

matteo.cocuzza@infm.polito.it

Simone Marasso

Tel. +39 011 911 4899

simone.marasso@polito.it

Porous 2D -3D materials for selective filtration

2D-materials such as graphene and its derivatives can be empoyed in innovative membranes for ultraselective separation. Nanoporous single layer graphene (SLG) -a graphene monolayer with high density of subnanometers pores- is predicted to allow ultrafast water permeance and high salt rejection, blocking the passage of solutes that are larger than the pores. Graphene oxide (GO), due to its natural hydrophilicity and intrinsic stacked structure, is successfully used for low-cost membranes made of channels whose dimension is slightly less than 1 nm.

SLG deposited on Cu foils by the Nano-CVD equipment is transferred to porous polymeric substrates to obtain a rigid membrane which can exploit nanofiltration properties due to the presence of nanopores in the SLG after the transfering. These nanopores must have nanometer and sub-nanometer dimensions in order to give selective rejection of the desired molecules present in water; they are present as native defects in the transferred SLG, or appositely created by plasma tretments. The rejection properties of the fabricated membranes are tested in a side-by-side filtration equipment.

Fig.1 – FESEM images of the Polycarbonate Track Etched PCTE substrate (a) and of two SLG/PCTE membranes (b) and (c); the red arrows indicate the presence of intrinsic defects and nano-pores

Using GO flakes dispersed in DI solutions, by vacuum filtration uniform GO membranes are produced on different polymeric supports with tunable thicknesses of the GO layer. After accurate drying steps, the membrane is employed in a dead-end filtering apparatus to measure the rejection towards Methylene Blue, Toluene, Methanol, Acetone and other organic compounds molecules.

Fig.2 – FESEM cross-section images of GO stacked membranes, at different magnification, the interlayer distance –confirmed by XRD- is of about 0.8 nm

Contact information

Stefano Bianco

stefano.bianco@polito.it

Andrea Lamberti

andrea.lamberti@polito.it

Elena Tresso

elena.tresso@polito.it

Publications

- "A new method to integrate ZnO nano-tetrapods on MEMS micro-hotplates for large scale gas sensor production", S.L. Marasso, A. Tommasi, D. Perrone, M. Cocuzza, R. Mosca, M Villani, A Zappettini and D. Calestani, Nanotechnology, 2016, Vol. 27(38), 385503, doi:10.1088/0957-4484/27/38/385503

- “Modeling, Fabrication and Testing of a Customizable Micromachined Hotplate for Sensor Applications”, A. Tommasi, M. Cocuzza, D. Perrone, C. F. Pirri, R. Mosca, M. Villani, N. Delmonte, A. Zappettini, D. Calestani and S. L. Marasso, Sensors, 2017, 17(1), 62, doi:10.3390/s17010062

- "The virtuous CO2 circle or the three C’s: capture, cache, convert", S. Bocchini, C. Castro, M. Cocuzza, S. Ferrero, G. Latini, A. Martis, C. F. Pirri, L. Scaltrito, V. Rocca, F. Verga, D. Viberti, Journal of Nanomaterials, Vol. 2017, Article ID 6594151, doi:10.1155/2017/6594151

- "Innovative technologies for offshore platforms safety and environmental monitoring", M. Cocuzza, L. Scaltrito, S. Ferrero, S.L. Marasso, D. Perrone, C.F. Pirri, Geoingegneria Ambientale e Mineraria (GEAM), Anno LIV, n. 3, Dicembre 2017, pp. 7-16

- "Cr(VI) in Water: Continuous, on Site Spectrophotometric Determination - Laboratory test preliminary to microfluidic device prototyping", F. Catania, A. Piscitelli, S. Ferrero, M. Cocuzza, C.F. Pirri, L. Scaltrito, M. Periolatto, Proc. of the Sixth Intl. Conf. Advances in Bio-Informatics, Bio-Technology and Environmental Engineering - ABBE 2018, ISBN: 978-1-63248-148-1, doi:10.15224/978-1-63248-148-1-01

- "Graphene-based membrane technology: reaching out to the oil & gas industry", C. Castro, M. Cocuzza, A. Lamberti, M. Laurenti, A. Pedico, F. Pirri, V. Rocca, E. Salina Borello, L. Scaltrito, C. Serazio, D. Viberti and F. Verga, Geofluids (2018), 7026426

- "Graphene oxide membranes for water purification", Pedico A., Lamberti A., Bianco S., Kara, S., Fontana M., Periolatto M, Pirri C.F., Tresso E., Presentation at the Conference MELPRO2018 Prague, Czech Republic, 13/05/2018-16/05/2018.

- "Fabrication of of nanoporous graphene membranes for nanofiltration applications", Laurenti, M.; Kara, S., Fontana, M., Bianco, S., Tresso, E., Pirri, C., Ferrero, S., Scaltrito, L., Invited Presentation at the 9th World Congress on Materials Science and Engineering, Rome (Italy) nel June 12-14, 2017.

- "Water purification by improved polymeric and graphene-based membranes", Pirri, C.F., Tresso E., Ciero G., Lamberti A., Laurenti M., Presentation at the OMC 2017 Confrence, Ravenna (Italy) 29-31 March 2017

- "Large area fabrication of self-standing nanoporous graphene-on-PMMA substrate", Clochard, M.-C., Melilli, G., Rizza, G., Madon, B., Alves, M., Wegrowe, J.-E., Toimil-Molares, M.-E., Christian, M., Ortolani, L., Rizzoli, R., Morandi, V., Palermo, V., Bianco, S., Pirri, F., Sangermano, M., (2016) Materials Letters, 184, pp. 47-51

Partners & Collaborations

IMEM-CNR - Parma

Società Metropolitana Acque Torino S.p.A.

ENI S.p.A.

Tecnomare S.p.A.

Ministero per lo Sviluppo Economico (MISE DGS-UNMIG)