Innovative solutions for Oil industry

In the oil industry one of the key issues to achieve better well productivity and increased recovery factor is the possibility to continuously and remotely monitor the reservoir behaviour so as to assess relevant formation and fluid properties and to foresee potential production problems. In this way hydrocarbon drainage could be optimized based on the knowledge of fluid flow in the reservoir. Furthermore, breakthrough of undesired fluids at the wells, and its consequences on the inflow performance, could be anticipated rather than faced after occurrence. Consideration should also be given to the modern integrated approach where surface facilities and pipeline network represent fundamental constraints to any development plans for new or existing fields, therefore monitoring should be extended to include fluid transport, treatment and disposal - if needed.

Furthermore, in a panorama of increasing interest for extreme exploration scenarios high-temperature, high-pressure reservoirs are becoming more and more attractive. However, sensors for reservoirs, wells and pipeline monitoring still suffer from several limitations, in terms of parameters they can measure, ability to transmit the acquired information to a collection center, average duration and working conditions (especially temperature) they can withstand. Data on instrument reliability are hardly available, but it is well known that several tools underwent unexpected premature cease of functioning.

The scope of this research activity is to carry out a technology development aimed at identifying potential miniaturised solutions and/or materials to be used for constructing innovative sensors and monitoring systems for different applicative scenarios: reservoir, well, pipeline and sub-marine environment. Different aspects are under investigation: sensors development, data communication and electronics, and energy harvesting.

The research and development activity is conducted in collaboration with other Research Groups of the Polytechnic of Turin belonging to the DIATI, DISAT and DET Departments

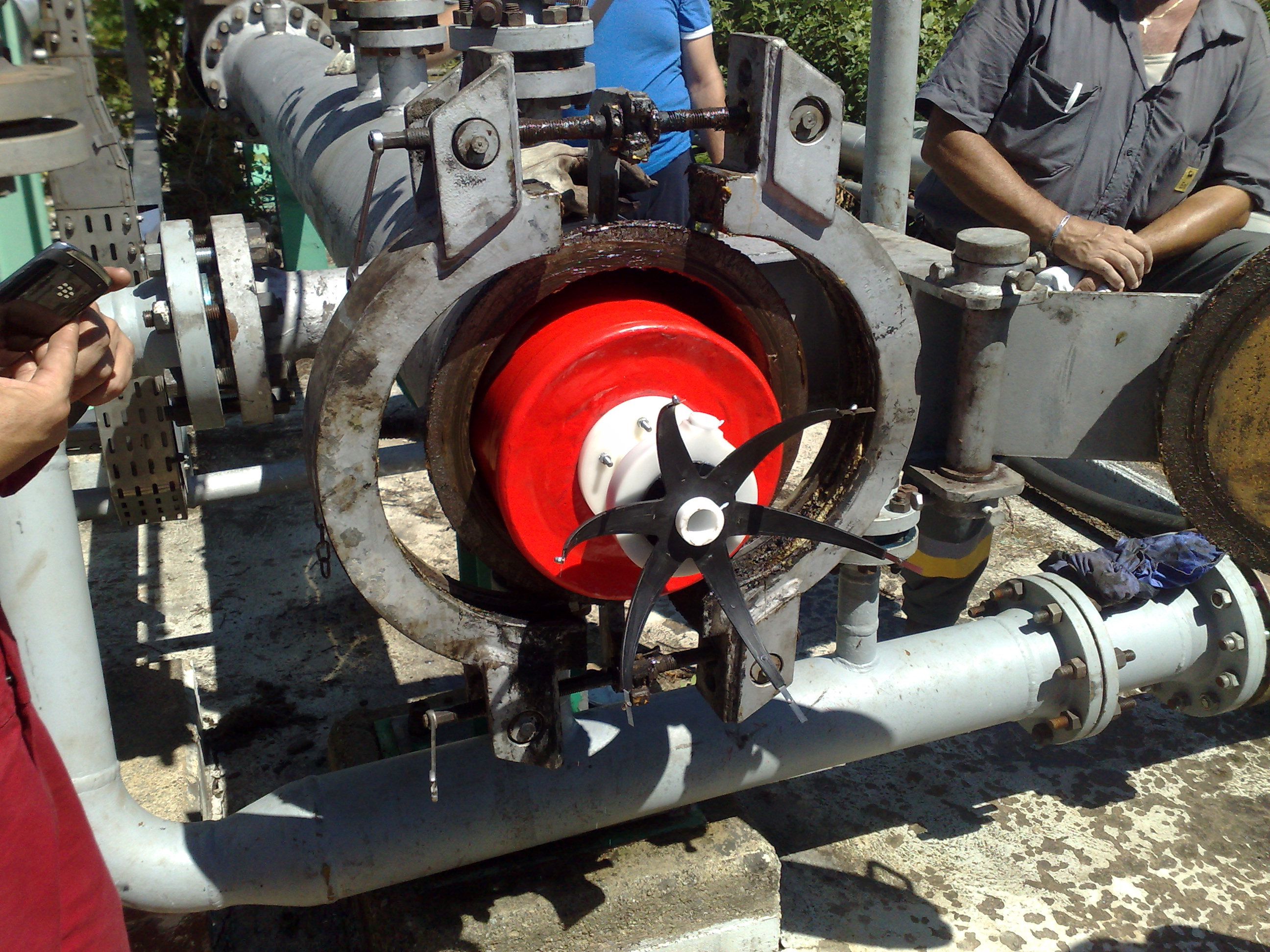

Smart Caliper Pipeline Inspection Gauge

We have developed a new, low-cost and low-risk foam pig with inspection capabilities similar to those of a multi-channel caliper pig (i.e. able to detect, locate and size inner diameter changes and deformations) together with additional features that allow to detect internal roughness changes useful for corrosion assessment purposes ("Pipeline inspection apparatus for the internal inspection of pipelines", US9599528(B2) ― 21/03/2017). One implementation of the new tool makes use of a foam pig “carrier”, providing the required push with a good capability to surpass restrictions, equipped with specialized sensors and modules for data acquisition and storage.

The previous prototype is currently updated to a new version with improved sensing capabilities, improved handling and exploitation and a breakthrough introduction of wireless communication, both during inspection mission to elaborate and store data, but also to download them in the post-mission session.

Contact information

Matteo Cocuzza

Tel. +39 011 090 7392

matteo.cocuzza@infm.polito.it

Giancarlo Canavese

Tel. +39 011 090 7389

giancarlo.canavese@polito.it

Microfluidics for in-field oil analysis

The characterization of reservoir fluids from the point of view of chemical composition and thermodynamic behavior is one of the key elements for the study, understanding and prediction of the production behavior of a hydrocarbon reservoir.

Samples of liquids from the reservoir come in the form of mixtures of hydrocarbons, often emulsified with water. However, the correct determination of the composition of the hydrocarbon mixture requires that it be pure, i.e. the aqueous phase is appropriately separated before chemical analysis such as infrared spectroscopy.

The analysis of the chemical composition of the reservoir fluids is carried out at different times both in specialized laboratories, and therefore in ideal working conditions, but also on-site and near the production plant. It is therefore particularly interesting to develop a small, and therefore transportable, instrument capable of performing the separation and characterization of the product oil reliably, in a short time and by using small volumes of fluid samples.

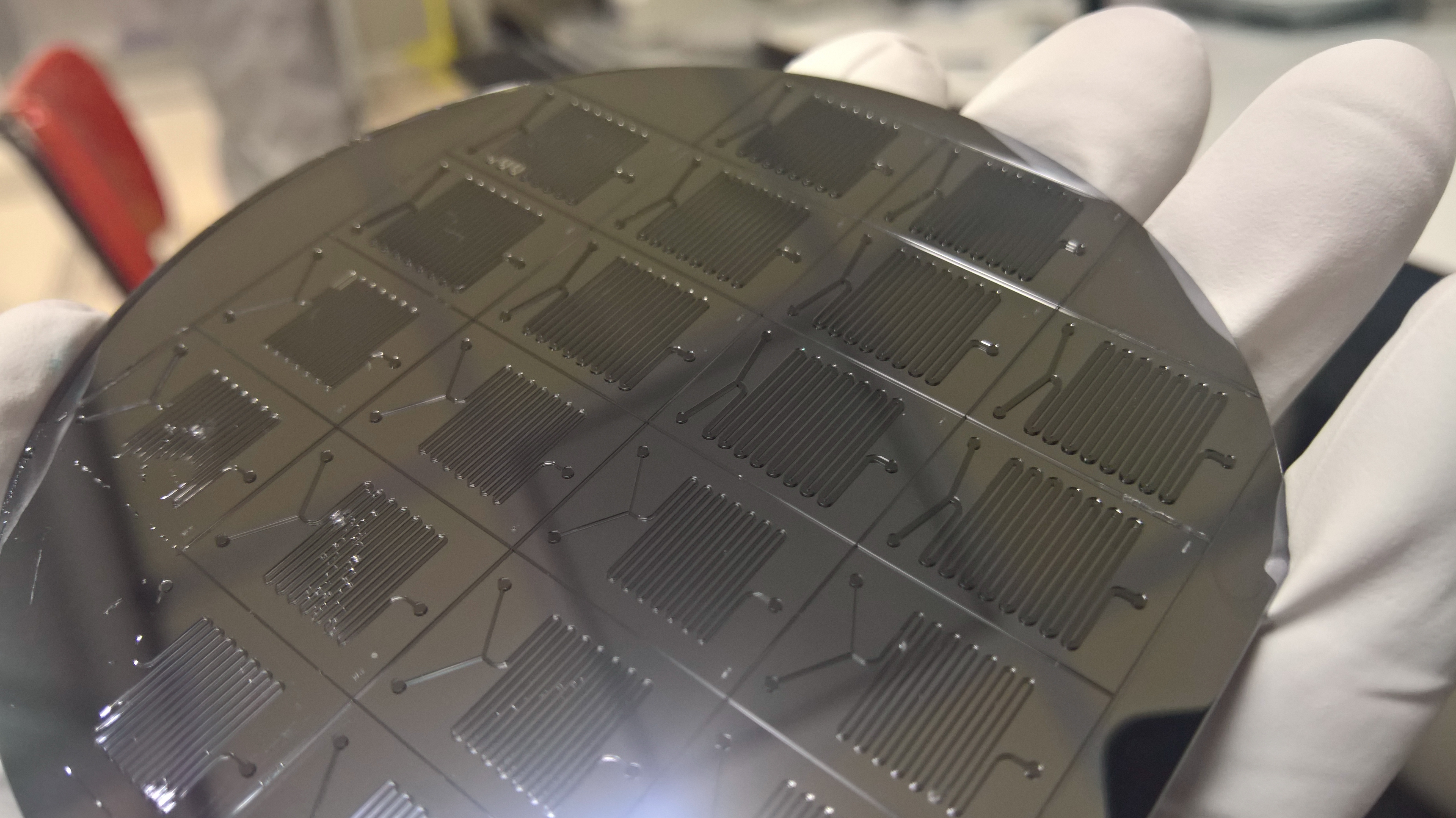

The aim of the research is to verify the feasibility, design, implementation and validation of a solution, based on microfluidic devices, aimed at the capillary separation of the oil and water phases for the subsequent characterization of the reservoir hydrocarbon mixture by infrared spectroscopy.

Contact information

Matteo Cocuzza

Tel. +39 011 090 7392

matteo.cocuzza@infm.polito.it

Simone Marasso

Tel. +39 011 911 4899

simone.marasso@polito.it

HP/HT Downhole Sensing

One of the fundamental aspects to improve well productivity and increase the recovery factor, as promised by the e-fields approach, lies in the possibility to continuously and remotely monitor the reservoir and wells with appropriate sensors, so as to ascertain the properties of the mineralized formation, the characteristics of the fluids contained therein and the mutual interactions and also determine the flows of oil, gas and water.

The aim of the activity is therefore to conceive, design, implement and test an advanced sensorized platform, based on acoustic principles for the monitoring of well and reservoir fluids, for monitoring the structural integrity of the well and for monitoring of the reservoir near the well, together with investigating and proposing possible solutions to the issues of electronic components and energy harvesting in harsh environment conditions.

Contact information

Luciano Scaltrito

Tel. +39 011 090 7337

luciano.scaltrito@polito.it

Sergio Ferrero

Tel. +39 011 911 7337

sergio.ferrero@polito.it

AUV for Offshore contamination detection

We also developed an instrumented pod for an Autonomous Underwater Vehicle (AUV) for the spectrophotometric detection of potential contaminants which may generated close to an underwater production site. The current system has been customized for the detection of heavy metallic ions and tested in a real application scenario.

Contact information

Luciano Scaltrito

Tel. +39 011 090 7337

luciano.scaltrito@polito.it

Sergio Ferrero

Tel. +39 011 911 7337

sergio.ferrero@polito.it

Porous 2D -3D materials for selective filtration

In the oil&gas industry the separation of contaminants from water and gas is of great interest. Both liquid and gas membrane operations might benefit from the employment of 2D materials. The research is devoted to unexplored technological solutions which can guarantee a reduced molecular pathway and higher selectivity.

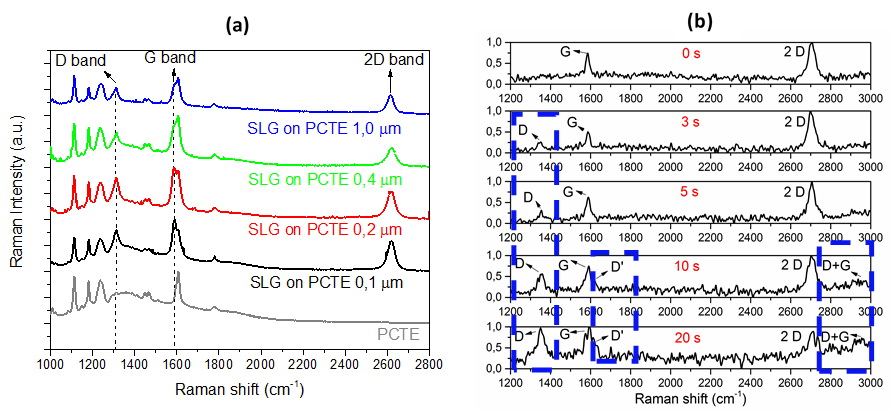

The presence of nanopores in the Single Layer Graphene (SLG) transferred to porous polymeric substrates can exploit nanofiltration properties. These nanopores must have nanometer and sub-nanometer dimensions in order to give selective rejection of the desired molecules; they are present as native defects in the transferred SLG, or they can be appositely created by plasma tretments. The rejection properties of the fabricated membranes are tested in a side-by-side filtration equipment.

Fig.1–Raman spectra of SLG/PCTE membranes at different PCTE-pore dimensions (a) and of a SLG/PCTE membrane subjected to O2 plasma treatment at different exposure times (b)

GO-stacked membranes produced by vacuum filtration on different polymeric supports are employed in a dead-end filtering apparatus. The first experimental results concern the rejection towards Methylene Blue, Toluene, Methanol, Acetone and other organic compounds molecules. Stability tests have been carried out leaving the GO membranes at rest immersed in different solutions for 1 month: the GO-stacked membranes showed high stability in presence of solvents, acids and salts.

Fig.2 – Comparison between the filtered solutions of the PCTE support membrane with respect to the GO/PCTE membrane, after filtration of an aromatic hydrocarbon solution in DI water

Contact information

Stefano Bianco

stefano.bianco@polito.it

Andrea Lamberti

andrea.lamberti@polito.it

Elena Tresso

elena.tresso@polito.it

Publications

-

"Design and characterization of microfluidic devices for water/oil separation", Quaglio, M., Frascella, F., Marasso, S.L., Cocuzza, M., Viberti, D., Amendola, A., Carminati, S., Fabrizio Pirri, C., Offshore Mediterranean Conference and Exhibition 2019, OMC 2019

-

"Spectrophotometric monitoring system, integrated in an autonomous underwater vehicle, for continuous monitoring", Periolatto, M., Catania, F., Pirri, F., Scaltrito, L., Offshore Mediterranean Conference and Exhibition 2019, OMC 2019

-

"Graphene-based membrane technology: reaching out to the oil & gas industry", C. Castro, M. Cocuzza, A. Lamberti, M. Laurenti, A. Pedico, F. Pirri, V. Rocca, E. Salina Borello, L. Scaltrito, C. Serazio, D. Viberti and F. Verga, Geofluids (2018), 7026426

-

"Graphene oxide membranes for water purification", Pedico A., Lamberti A., Bianco S., Kara, S., Fontana M., Periolatto M, Pirri C.F., Tresso E. Presentation at the Conference MELPRO2018 Prague, Czech Republic, 13/05/2018-16/05/2018.

-

"Fabrication of of nanoporous graphene membranes for nanofiltration applications", Laurenti, M.; Kara, S., Fontana, M., Bianco, S., Tresso, E., Pirri, C., Ferrero, S., Scaltrito, L., Invited Presentation at the 9th World Congress on Materials Science and Engineering, Rome (Italy) nel June 12-14, 2017.

-

"Water purification by improved polymeric and graphene-based membranes", Pirri, C.F., Tresso E., Ciero G., Lamberti A., Laurenti M., Presentation at the OMC 2017 Conference, Ravenna (Italy) 29-31 March 2017

-

"Cr(VI) in Water: Continuous, on Site Spectrophotometric Determination - Laboratory test preliminary to microfluidic device prototyping", F. Catania, A. Piscitelli, S. Ferrero, M. Cocuzza, C.F. Pirri, L. Scaltrito, M. Periolatto, Proc. of the Sixth Intl. Conf. Advances in Bio-Informatics, Bio-Technology and Environmental Engineering - ABBE 2018, ISBN: 978-1-63248-148-1, doi:10.15224/978-1-63248-148-1-01

-

"Innovative technologies for offshore platforms safety and environmental monitoring", M. Cocuzza, L. Scaltrito, S. Ferrero, S.L. Marasso, D. Perrone, C.F. Pirri, Geoingegneria Ambientale e Mineraria (GEAM), Anno LIV, n. 3, Dicembre 2017, pp. 7-16

-

"Large area fabrication of self-standing nanoporous graphene-on-PMMA substrate", Clochard, M.-C., Melilli, G., Rizza, G., Madon, B., Alves, M., Wegrowe, J.-E., Toimil-Molares, M.-E., Christian, M., Ortolani, L., Rizzoli, R., Morandi, V., Palermo, V., Bianco, S., Pirri, F., Sangermano, M., (2016) Materials Letters, 184, pp. 47-51

-

"A novel Smart Caliper Foam pig for low-cost pipeline inspection – Part A: Design and Laboratory Characterization", C. Ramella, G. Canavese, S. Corbellini, M. Pirola, M. Cocuzza, L. Scaltrito, S. Ferrero, C.F. Pirri, G. Ghione, F. Verga, A. Tasso, A. Di Lullo, Journal of Petroleum Science and Engineering, 2015, March 2015, Vol. 127, pp. 311-317, doi:10.1016/j.petrol.2015.01.008

-

"A novel Smart Caliper Foam pig for low-cost pipeline inspection – Part B: Field Test and data processing", C. Ramella, G. Canavese, S. Corbellini, M. Pirola, M. Cocuzza, L. Scaltrito, S. Ferrero, C.F. Pirri, G. Ghione, V. Rocca, A. Tasso, A. Di Lullo, Journal of Petroleum Science and Engineering, 2014, September 2015, Vol. 133, pp. 771-775, http://dx.doi.org/10.1016/j.petrol.2014.09.038

-

"Current and future nanotech applications in the oil industry”, Cocuzza M., Pirri C. F., Rocca V. and Verga F., Am. J. Applied Sci., 2012, 9, pp. 784-793, doi: 10.3844/ajassp.2012.784.793

-

"Is the oil industry ready for nanotechnologies", M. Cocuzza, C. F. Pirri, V. Rocca, F. Verga, Proceedings of the 10th Offshore Mediterranean Conference (OMC), Ravenna (Italy), March 23-25, 2011

Patents

- "PIPELINE INSPECTION APPARATUS FOR THE INTERNAL INSPECTION OF PIPELINES", Inventors: A. Di Lullo, M. Pirola, L. Scaltrito, J.M. Tulliani. Assignee: ENI S.p.A., WO2013102807 (A3) ― 24/10/2013 & US9599528(B2) ― 21/03/2017