RESEARCH IN OUR LAB

Below is a description of the most important topics of research in our lab. To know what happens in our Department, please visit the webpage of DIATI.

Membrane-Based Separation for Water Purification

We advance membrane-based processes for the purification and valorization of water and wastewater streams. We fabricate and functionalize membranes for water decontamination and we study and optimize technologies deploying these membranes. We employ various techniques, such as interfacial polymerization, phase separation, layer-by-layer assembly, surface grafting and functionalization to fabricate our membranes. For testing and process optimization, we are currently equipped with the following bench-scale setups:

- one cross-flow reverse osmosis/nanofiltration system (5-70 bar) accommodating flat sheet membranes

- one dead-end ultrafiltration or low-pressure nanofiltration system (0.5-5 bar) accommodating flat sheet membranes

- one cross-flow ultrafiltration or low pressure nanofiltration system (0.5-10 bar) accommodating both flat sheet membranes and small-scale tubular ceramic membranes

- two forward osmosis systems (flat sheet membranes), one system for membrane samples of size 20 cm2, the second system, a bit larger, for membrane size of 140 cm2

- three membrane distillation systems (flat sheet membranes), for membrane samples of sizes, 20 cm2, 125 cm2, and 500 cm2

- a dead-end reverse osmosis/nanofiltration setup (5-70) bar for flat sheet membranes (diameter of 7 cm)

- a single module ceramic micro/ultrafiltration setup

- glass diffusion cell, with the possibility of also measuring the water passage if used in flux mode, for circular flat sheet membranes of 1.4 cm diameter

We also work with pilot systems: currently, we have experiments ongoing with a 2-module nanofiltration system. We own a SurPASS™ 3 electrokinetic analyzer for the characterization of the surface potential of membranes. This system can also be used for other flat solid samples, as well as fibers and fabrics, granular samples, and coarse particles. We make use of several other membrane characterization techniques and instrumentation also in collaboration with colleagues in DISAT Department, as well as in shared facilities of our Department or of Politecnico di Torino. We also work hand in hand with a new interdepartmental center devoted to technology transfer of innovative water treatment technologies, the CleanWaterCenter@PoliTo.

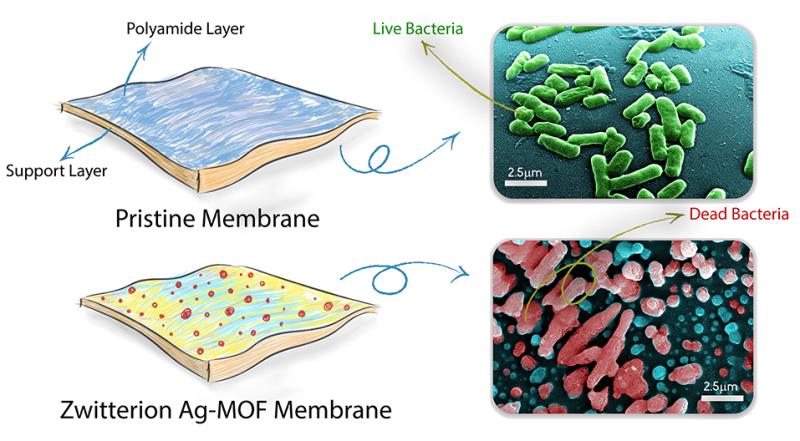

Novel Materials for Membrane Fabrication and Functionalization

Every application requires a membrane with target properties. In our lab, we investigate novel chemistries and novel fabrication protocols to obtain a final product that is adequate for specific applications, such as removal of specific contaminants or achievement of production goals. These studies include the optimization of membrane charge, transport properties, pore size and density, and surface chemistry. Examples of this research include membrane functionalization with metal-organic frameworks (MOFs), biocide nanomaterials, and superhydrophilic materials to reduce (bio)fouling or to control the surface tension at the water/membrane interface. These membranes are applied in ultrafiltration, nanofiltration, reverse osmosis, engineered osmosis, or membrane distillation. See examples: 10.1016/j.memsci.2017.06.034, 10.1016/j.memsci.2017.08.067, and 10.1021/acsami.0c12141.

Wastewater Reuse through Membrane Processes

We investigate the best practices and the most promising solutions to desalinate and purify wastewater with the goal to reuse for civil, agricultural, and industrial uses. In particular, we are currently interested in the reuse of produced water (wastewater of oil & gas industry) (see 10.1038/s41598-019-51167-z), and in resource recovery by integrating membrane systems with large-scale washing machines in the laundering industry (see 10.5004/dwt.2017.201 or 10.1016/j.jclepro.2017.04.012).

Membrane Pilot Systems for Contaminant Removal and Powered by Renewable Energy

We install and operate pilot systems aimed at the removal of specific target contaminants or with the goal to improve membrane-based separation systems run on renewable energy sources. Currently, we are studying the behavior of a nanofiltration pilot plant to treat well water contaminated with chromium to produce safe potable water; see 10.1007/s11356-018-2627-5 or 0.1016/j.jece.2018.06.055. Also, we collaborate with colleagues in the Energy Department to exploit the sun and waste heat streams as potential energy sources for high-end treatment applications.

Advanced Oxidation Processes for Water Purification

Homogeneous and Heterogeneous Catalytic Degradation of Contaminants

We investigate the efficiency and the mechanisms of contaminant degradation by oxidative catalytic processes. For example, we apply homogeneous and heterogeneous Fenton and Fenton-like reactions for the abatement of contaminants of emerging concern. We also study novel catalytic molecules based on organometallic complexes (e.g., iron complexes with organic ligands) to perform the same homogeneous reaction near neutral pH, with minimization of sludge production, and mimicking the activity and function of biological heme groups. Furthermore, we design, synthesize, and engineer novel heme mimics to be used in homogeneous and heterogeneous, i.e., fixed on a solid support, reaction. See for an example: 10.1016/j.jhazmat.2020.122413.

Coupling of Membrane and Advanced Oxidation Processes

The coupling of the oxidation processes with a separative step able to selectively remove specific compounds and contaminants from water is potentially very advantageous in the framework of water reuse systems. Separation and degradation are in fact complementary mechanisms to purify water and they may be applied in synergy to ensure a water effluent of high quality. Therefore, we propose and we evaluate the coupling of membrane processes with oxidation treatments to enhance the latter and to optimize the overall treatment train. One instance is the use of low-pressure nanofiltration to remove organic matter and other scavengers from wastewater, thereby enhancing the cost- and energy-efficiency of the Fenton reaction. See for an example: 10.1021/acsomega.8b01055. We own a Shimadzu TOC analyzer for the determination of dissolved organic and inorganic carbon.

Nanomaterials in the Aqueous Environment and Their Applications to Reclaim Contaminated Sites

In collaboration with the lab of Prof. Sethi, we are equipped with a light scattering instrument (Malvern ZetaSizer Plus ZSP), UV-vis spectrophotometers, a viscosity meter, an automatic titrator, various column systems for the measurement of particle mobility, and various 2D setups for transport on porous media. For quality analyses, we make use of ionic chromatography and inductively coupled plasma (ICP) systems owned by our colleagues in DIATI with whom we collaborate.

Behavior of Nanomaterials in Aqueous Environments

Our research includes the understanding of stability and sedimentation phenomena of nanomaterials in aqueous environments. This behavior controls the fate and transport of nanomaterials. We study the effect of various chemical conditions and how the presence of specific components affects particle behavior; see for an example 10.1007/s11051-017-3814-x.

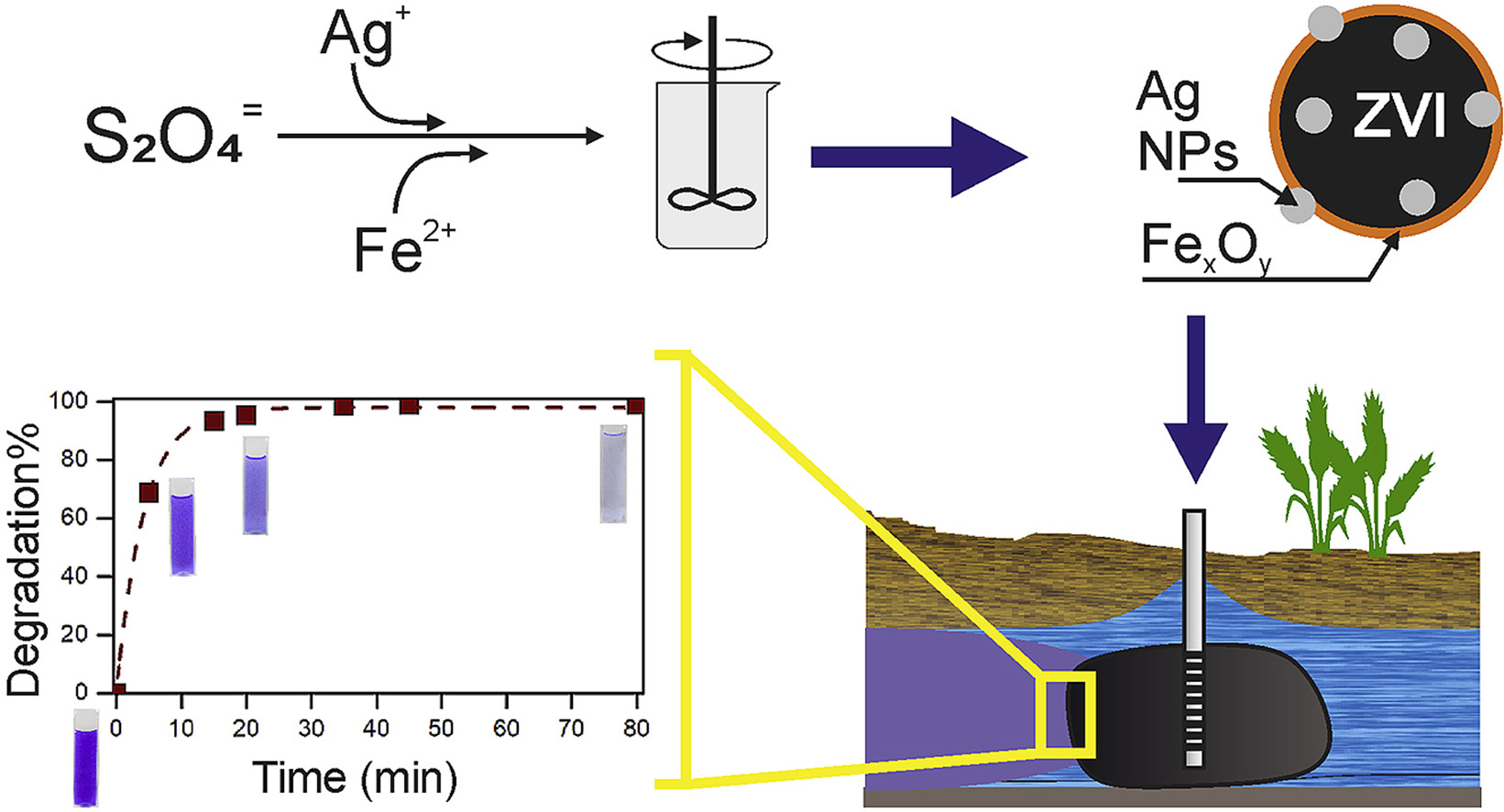

Nanomaterials for Site Remediation

Our group collaborates with researchers in the lab of Prof. Sethi to propose nanomaterials as cleaning agents for sites contaminated by non-aqueous phase liquids, heavy metals, and emerging contaminants. In particular, iron-based particles are promising materials to promote reductive dechlorination or aerobic biodegradation of many dangerous contaminants currently present in the subsoil worldwide. The use of iron-based particles as a remediation technology requires a complete understanding of their behavior and reactivity under real field conditions. See some publications related to this topic at 10.1038/s41598-017-13423-y or 10.1016/j.jclepro.2018.10.298.

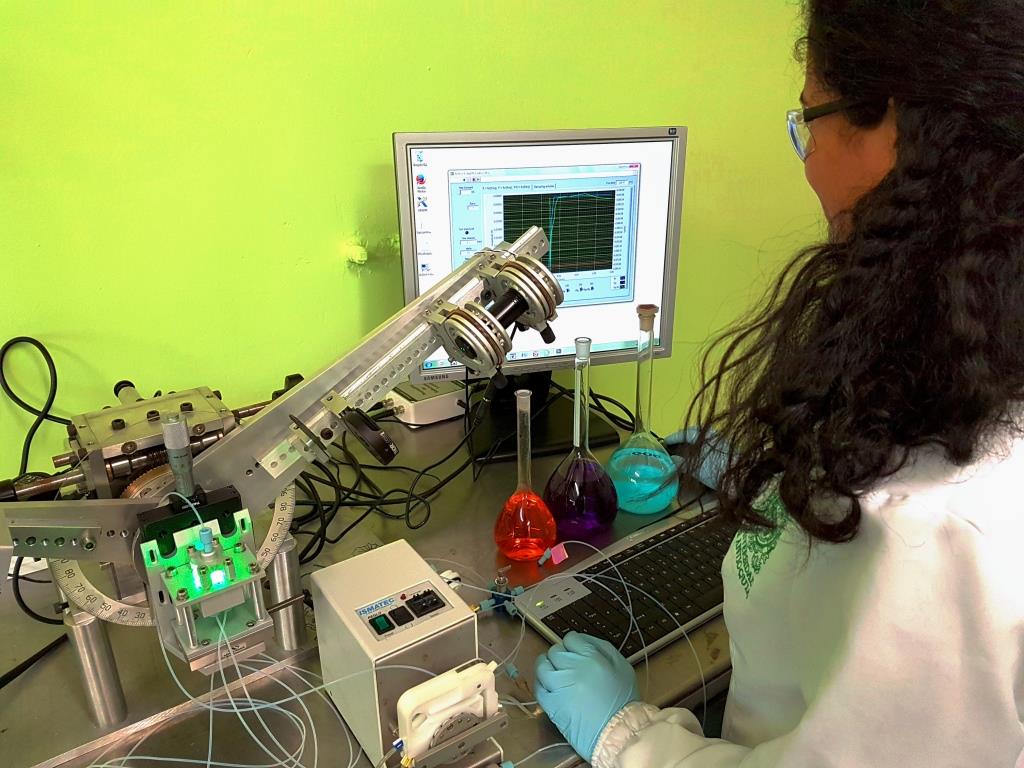

Interaction of Macromolecules and Particles with Solid Surfaces

We own a reflectometer, equipped with a 532 nm wavelength laser.

Adsorption and Desorption of Polymers from Solid Surfaces

Polymers and macromolecules are ubiquitous in aquatic environments. Adsorbed polymers on particle surfaces govern the behavior of these materials in aqueous suspensions. In the natural environment, particles are typically modified by adsorption of natural organic matter (NOM), which affects their fate and transport. In engineered processes, adsorption of polymers is commonly exploited to either enhance colloidal stability or to induce particle aggregation: for example, the addition of polyelectrolytes, metal salts, or both, is an established procedure to achieve promote flocculation and sedimentation in both wastewater and water treatment plants. Furthermore, attachment of macromolecules on the membrane surface is the first step that eventually leads to fouling and biofouling and the related loss of process performance. Understanding the mechanisms of adsorption and desorption of macromolecules on/from a solid surface is fundamental to be able to control these processes and to ensure the achievement of engineering goals in technologies that rely on such phenomena. See an example of publication at 10.1021/acs.langmuir.8b02573.