Thermo-gravimetric analyzer

Features

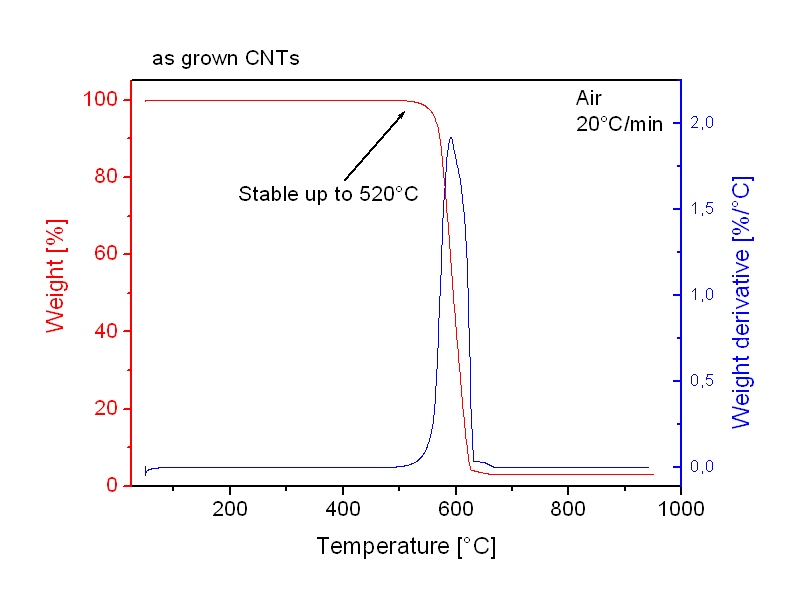

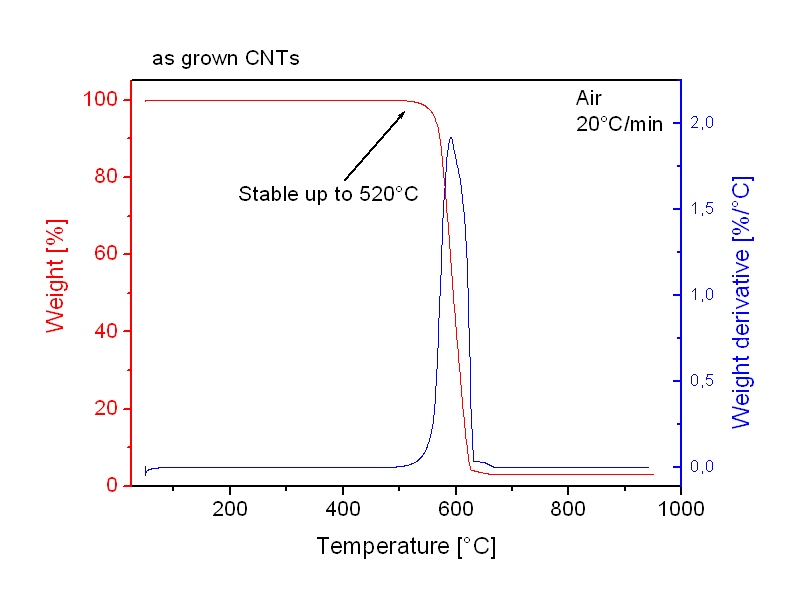

Thermogravimetric Analysis or TGA is a type of testing that is performed on samples to determine changes in weight in relation to change in temperature. Such analysis relies on a high degree of precision in three measurements: weight, temperature, and temperature change.

As many weight loss curves look similar, the weight loss curve may require transformation before results may be interpreted. A derivative weight loss curve can be used to tell the point at which weight loss is most apparent. Again, interpretation is limited without further modifications and deconvolution of the overlapping peaks may be required.

The analyzer usually consists of a high-precision balance with a pan loaded with the sample. The sample is placed in a small electrically heated oven with a thermocouple to accurately measure the temperature.

The atmosphere may be purged with an inert gas to prevent oxidation or other undesired reactions. A computer is used to control the instrument.

Analysis is carried out by raising the temperature gradually and plotting weight against temperature. After the data is obtained, curve smoothing and other operations may be done such as to find the exact points of inflection.

Significance of TGA in CNT

This technique is often employed not just to investigate the thermal stability of the material but also to provide information concerning the purity,

the amount of metal particles and the presence of defects.

The analysis can be performed either in nitrogen gas flow or in air flow, althought, while TGA measurements in nitrogen gas give few information because of the negligible

weight loss of the material due to its high stability in such an inert environment, TGA technique in oxidative atmosphere can play a threefold role:

- The metal content of CNTs can be estimated by evaluating the residual weight % at the endo of the thermal-oxidative curve

- The start temperature of the oxidative process can be correlated with the presence of lattice defect, either of the pristine material or after any treatment (i.e. the less the defects, the higher the temperature)

- The shape of the weight derivative (w %/°C) curve throughout the analysis can give some information about the presence of carbon by products, such as amorphous carbon,

in the pristine material. Indeed carbonaceous particles are presumably burned out first due to the selective etching at faster oxidative etching rate than CNTs. On the other hand, the shape of the curve can also be used

to evaluate the modification of the CNTs structure after functionalization treatment.

View in

High res