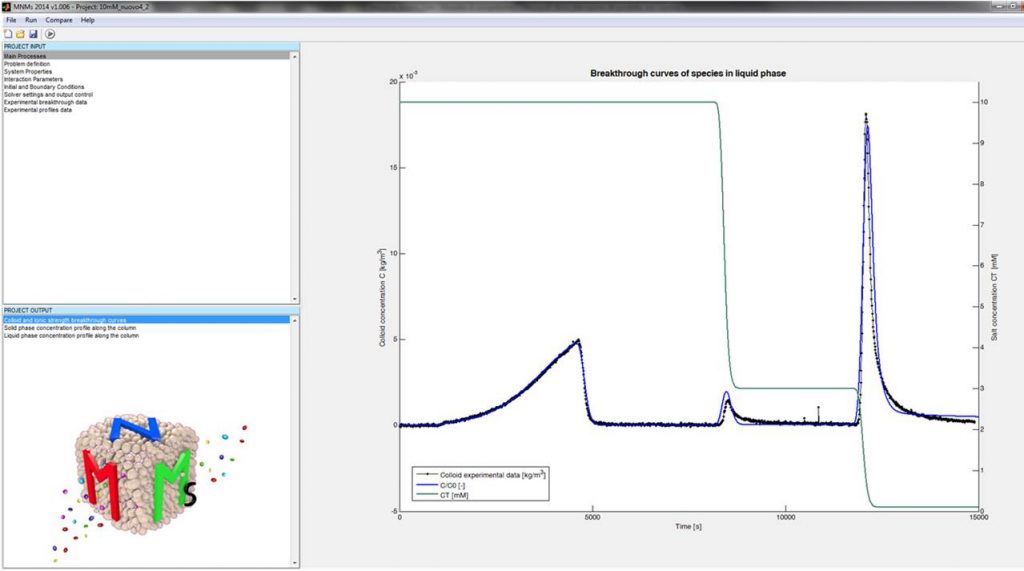

MNMs 2021 (Micro-and Nanoparticle transport, filtration and clogging Model – Suite) is a software tool for the simulation of colloid transport in porous media and represents the evolution of MNM1D and E-MNM1D, whose features are here merged into one software. As such, MNMs allows simulations of colloid transport in the presence of both constant and transient hydrochemical conditions, with eventual clogging of the porous medium.

MNMs 2021 (Micro-and Nanoparticle transport, filtration and clogging Model – Suite) is a software tool for the simulation of colloid transport in porous media and represents the evolution of MNM1D and E-MNM1D, whose features are here merged into one software. As such, MNMs allows simulations of colloid transport in the presence of both constant and transient hydrochemical conditions, with eventual clogging of the porous medium.

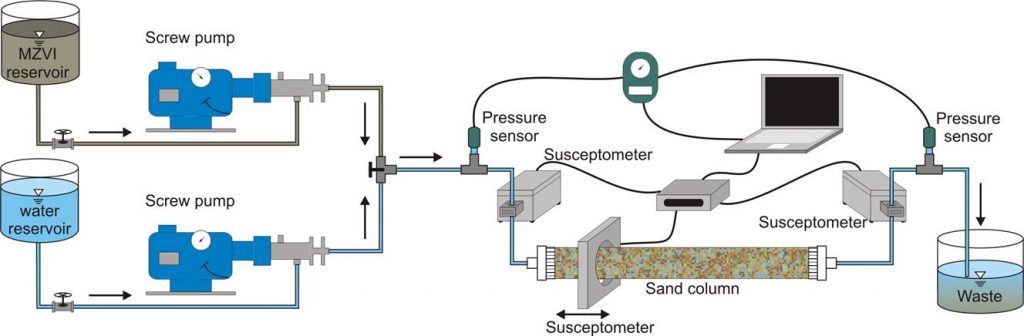

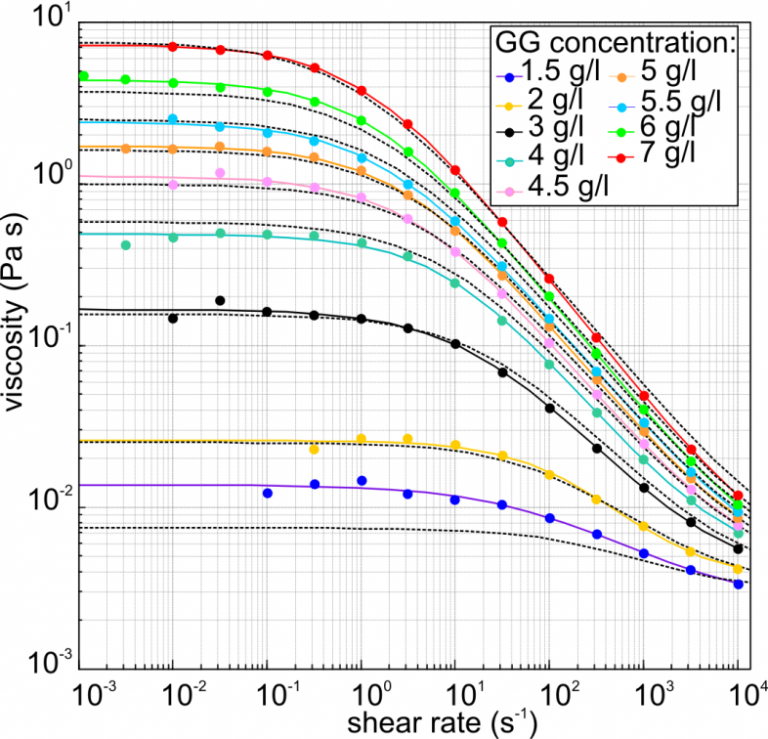

MNMs can be run in direct mode (predictive simulations) and in inverse model (data fitting), thus allowing the user to estimate the colloidal transport kinetic coefficients as a result of the interpretation of laboratory transport test outcomes. It takes into account attachment and detachment phenomena, that can be modeled with one or two interaction sites. The deposition phenomenon at each site can be modeled by means of several kinetics: linear, blocking, ripening and/or straining. MNMs can also take into account phenomena of porous medium clogging, simulating the pressure drop increase during the deposition of colloidal particles. The non-Newtonian nature of carrier fluids usually employed to improve stability of iron particles is also simulated.

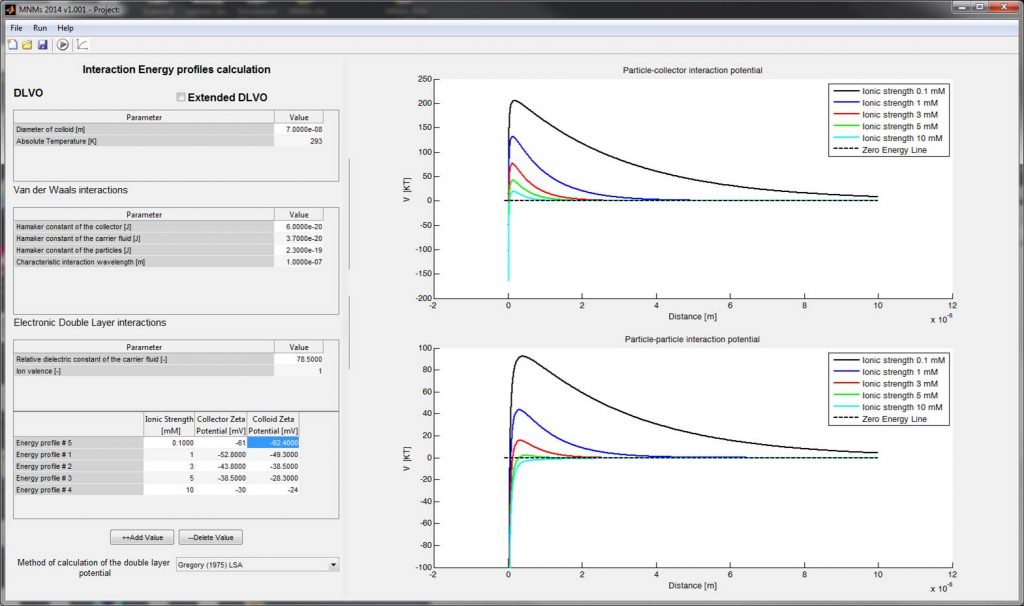

MNMs also provides tools for tracer test interpretation, both analytically and numerically, and for calculation of particle-particle and particle-collector interaction energy profiles following the DLVO theory approach.

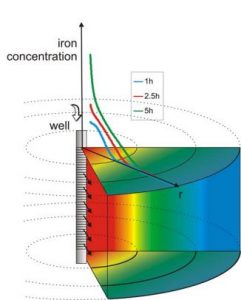

The last release of MNMs includes a comprehensive transport model of particle suspensions in radial coordinates [Tosco, Gastone, Sethi, 2014] which takes into account the non-Newtonian (shear thinning) rheological properties of the dispersant fluid and the porous medium clogging associated with filtration and sedimentation in the porous medium of both particles. Transport and flow equations are solved in radial geometry accounting for attachment and detachment dependency on pore fluid velocity and viscosity.

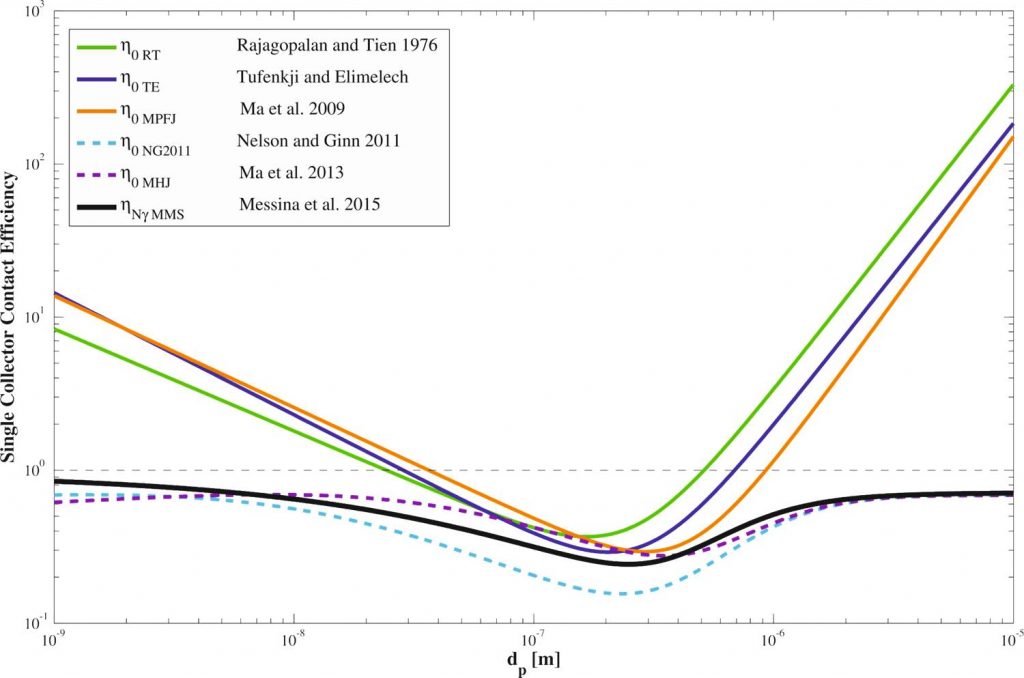

The formulations of the kinetic coefficients dependency on the velocity of the carrier fluid that are available in literature are commonly based on the concepts of single collector efficiency (Logan et al. 1995; Yao et al. 1971), for the attachment coefficient, and of drag force (Li et al.), for the detachment coefficient. MNMs implements several formulations from different authors for the calculation of single collector efficiency, such as the classical formulation proposed by Yao 1971 and the new ηMMs proposed by Messina et al. 2015. In particular, the new correlation equation ηMMs provides efficiency values lower than one over a wide range of parameters and it is valid for both point and finite-size particles.

In addition, MNMs also implements a dedicated tool for the calculation of the single collector efficiency using up to seven different formulations available in the literature. The user can compare the single collector efficiency curves obtained from different formulations or use different system properties in order to forsee the particle behavior in the porous medium.

See the reference notes for more details.

The governing equations are solved using a finite-difference approach. The model is developed in a Matlab environment and provided as a standalone application, that can be run on machines that have already installed the Matlab Compiler Runtime (MCR).

The Matlab Compiler Runtime (R2010b ver. 7.14) is required for running the software. It is provided within the installation package or can be downloaded separately.

The file provided here is a demo version. The demo version has the same features of the licensed one, except for the possibility to save your own projects and export simulation results. For the full featured version please contact: carlo.bianco[at]polito.it or tiziana.tosco[at]polito.it.

Help us to improve MNMs, please report any error, bug or suggestion.

Licensed istitutions

Austrian Institute of Technology – Department of Health & Environment;

Bioforsk – Norwegian Institute for Agriculture and Environmental Research;

Bone Environmental Consultant Ltd.;

Comisión Nacional de Energía Atómica (CNEA) – División Química de la Remediación Ambiental

Deltares;

Helmhotz Centre for Environmental Research – UFZ;

Helmholtz-Zentrum Dresden – Reactive Transport Division of the Institute of Resource Ecology;

Helmhotz Zentrum Munchen – Insitute of Groundwater Ecology;

Institut de Mécanique et d’Ingénierie – TREFLE Fluides et Transferts – Bordeaux

Intrapore GmbH – Essen (Germany)

Jacobs University Bremen – Downstream BioProcessing Laboratory;

KAUST King Abdullah University of Science and Technology – Computational Transport Phenomena Laboratory;

Slovak University of Technology in Bratislava – Department of Mathematics and Descriptive Geometry;

Stockholm University – Department of Physical Geography

Stuttgart University – Institute for Modelling Hydraulic and Environmental Systems – VEGAS facilities;

Teesside University – School of Science, Engineering & Design;

The French National Institute for Agricultural Research;

UC Davis – University of California, Civil & Environmental Engineering;

University of Chemistry and Technology, Prague (UCT);

University of Gothenburg, Sweden – Department of Chemistry & Molecular Biology

The Sir Colin Campbell Building University of Nottingham Innovation Park –Land Quality Management Ltd.;

University of Leeds – School of Chemical and Process Engineering;

University of Manchester – School of Earth, Atmospheric and Environmental Sciences;

University of Potsdam – Institute of Earth and Environmental Science

University of Tehran;

University of Utrecht – Department of Earth Sciences;

University of Vienna – Department of Environmental Geosciences;

Vienna University of Technology – Institute of Hydraulic Engineering and Water Resources Management.

Support

Contact us at: mnms.help@gmail.com

Installation guide for Windows

Step by step tutorial + example files

MNMs discussion forum

MNMs history

Download last release

MCR – Matlab Compiler Runtime

For MNMs 3.007 or higher: MCR R2017b

For MNMs 3.005 or lower: MCR 7.14 32 bit / 64 bit

MNMs software

MNMs software

MNMs 2021 v. 3.019 (18-10-2021)

MNMs 2018 v. 3.018 (28-08-2020)

MNMs 2018 v. 3.014 (25-03-2020)

References

SINGLE COLLECTOR EFFICIENCY

Messina, M.; Marchisio, D.; Sethi, R., 2015. An extended and total flux normalized correlation equation for predicting single-collector efficiency. Journal of Colloid and Interface Science, Volume 446, 15 May 2015, Pages 185-193. [link]

INFLUENCE OF IONIC STRENGTH

Tosco, T.; Tiraferri, A.; Sethi, R., 2009. Ionic Strength Dependent Transport of Microparticles in Saturated Porous Media: Modeling Mobilization and Immobilization Phenomena under Transient Chemical Conditions. Environmental Science & Technology , 43(12), 4425-4431. [link]

Tosco, T.; Sethi, R., 2009. MNM1D: a numerical code for colloid transport in porous media: implementation and validation. American Journal of Environmental Sciences , 5(4), 517-525. [link]

Tiraferri, A.; Tosco, T.; Sethi, R., 2011. Transport and retention of microparticles in packed sand columns at low and intermediate ionic strengths: Experiments and mathematical modeling. Environmental Earth Sciences , 63(4), 847-859. [link]

Tosco, T.; Bosch, J.; Meckenstock, R.U.; Sethi, R., 2012. Transport of ferrihydrite nanoparticles in saturated porous media: role of ionic strength and flow rate. Environmental Science and Technology, 63 (4), pp. 847-859. [link]

NON-NEWTONIAN SUSPENSIONS

Tosco, T.; Sethi, R., 2010. Transport of non-newtonian suspensions of highly concentrated micro- and nanoscale iron particles in porous media: A modeling approach. Environmental Science and Technology, 44(23), 9062-9068. [link]

Hosseini, S.M.; Tosco,T., 2013. Transport and retention of high concentrated nano-Fe/Cu particles through highly flow-rated packed sand column. Water Research, 47 (1), pp. 326-338. [link]

Gastone, F.; Tosco, T; Sethi, R., 2014. Guar gum solutions for improved delivery of iron particles in porous media (Part 1): Porous medium rheology and guar gum-induced clogging. Journal of Contaminant Hydrology, 166, pp. 23-33 [link]

RADIAL GEOMETRY

Tosco, T; Gastone, F.; Sethi, R., 2014. Guar gum solutions for improved delivery of iron particles in porous media (Part 2): Iron transport tests and modeling in radial geometry. Journal of Contaminant Hydrology 166, pp. 34-51 [link]

3D GEOMETRY

Bianco, C; Tosco, T.; Sethi, R., 2016. A 3-dimensional micro- and nanoparticle transport and filtration model (MNM3D) applied to the migration of carbon-based nanomaterials in porous media. Journal of Contaminant Hydrology 193, pp. 10-20 [link]