Micro Powder Blasting

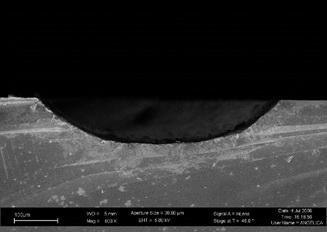

Powder blasting, or abrasive jet machining (AJM), is a technique in which a particle jet is directed towards a target for mechanical material removal.

It is a fast, cheap and accurate directional etch technique for brittle materials such as glass, silicon and ceramics.

The particle jet can be optimized for etching, while an eventual mask (according to the geometries to be patterned), made of a photosensitive polymeric layer, defines the small and complex structures to be etched.

It is a fast process; the time to etch through a 1.5 mm thick quartz wafer with one nozzle is approximately 60 secs in our set-up based on a Model HME II Unit from S.S. White Technologies, Inc. (151 Old New Brunswick Road, Piscataway, NJ08854). The particles are accelerated towards the target with a high-pressure dried air jet. The airflow is mixed with the particles by a vibrating feeder. The mixture is directed through a circular tungsten nozzle (with a diameter variable from 0.35 to 0.8 mm) at the end of the tube. The particles hit the target with a speed, depending on the air pressure, in a separate box. Particles are made of alumina with a grain size variable from 23 to 95 mm.

Our system is based on a 3-axis robot PC interfaced system, with the nozzle scanning path designed and optimised with a CAD tool.