FDM 3D Printer

FDM – Ultimaker S5

Fused Deposition Modeling (FDM) represents an additive manufacturing process which consists in the creation of a three-dimensional object by consecutive deposition of a melted thermoplastic filament.

In our lab we are provided with the Ultimaker S5 which is equipped with a double extruder for multi-material printing of both commercial and customized filaments

Technical data:

- Double extruder with interchangeable nozzles

- Building area: XYZ: 330 x 240 x 300 mm

- Filament diameter: 2.85 mm

- Vertical resolution: 0.25 mm nozzle: 150 – 60 micron; 0.8 mm nozzle: 600 – 20 micron; 0.4 mm nozzle 200 – 20 micron

- Axes accuracy: XYZ: 6.9, 6.9, 2.5 micron

- Print speed: <24 mm3/s

- Plate temperature range: 20 – 140 °C

- Available noozles: 0.25 mm, 0.4 mm, 0.8 mm

- Nozzle temperature range: 180 – 280 °C

- Nozzle heating time: <2 min

- Plate heating time: <4 min

Ultimaker available materials:

- PLA

- Tough PLA

- Nylon

- ABS

- CPE

- PC

- TPU 95A

- PP

- PVA

- Breakaway

- Works also with third-party materials

The printer can work with models in the formats:

- STL

- OBJ

- X3D

- 3MF

- BMP

- GIF

- JPG

- PNG

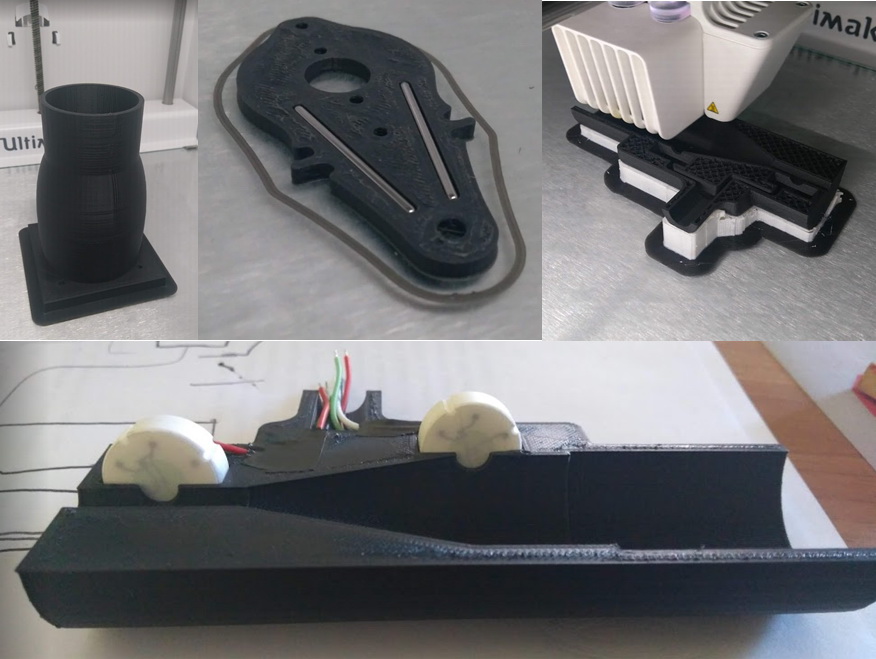

Some components built with the printer, with examples of parts integrations:

We are currently testing the performance of polylactic acid (PLA) carbon based composites to obtain electrical contact and sensing features.